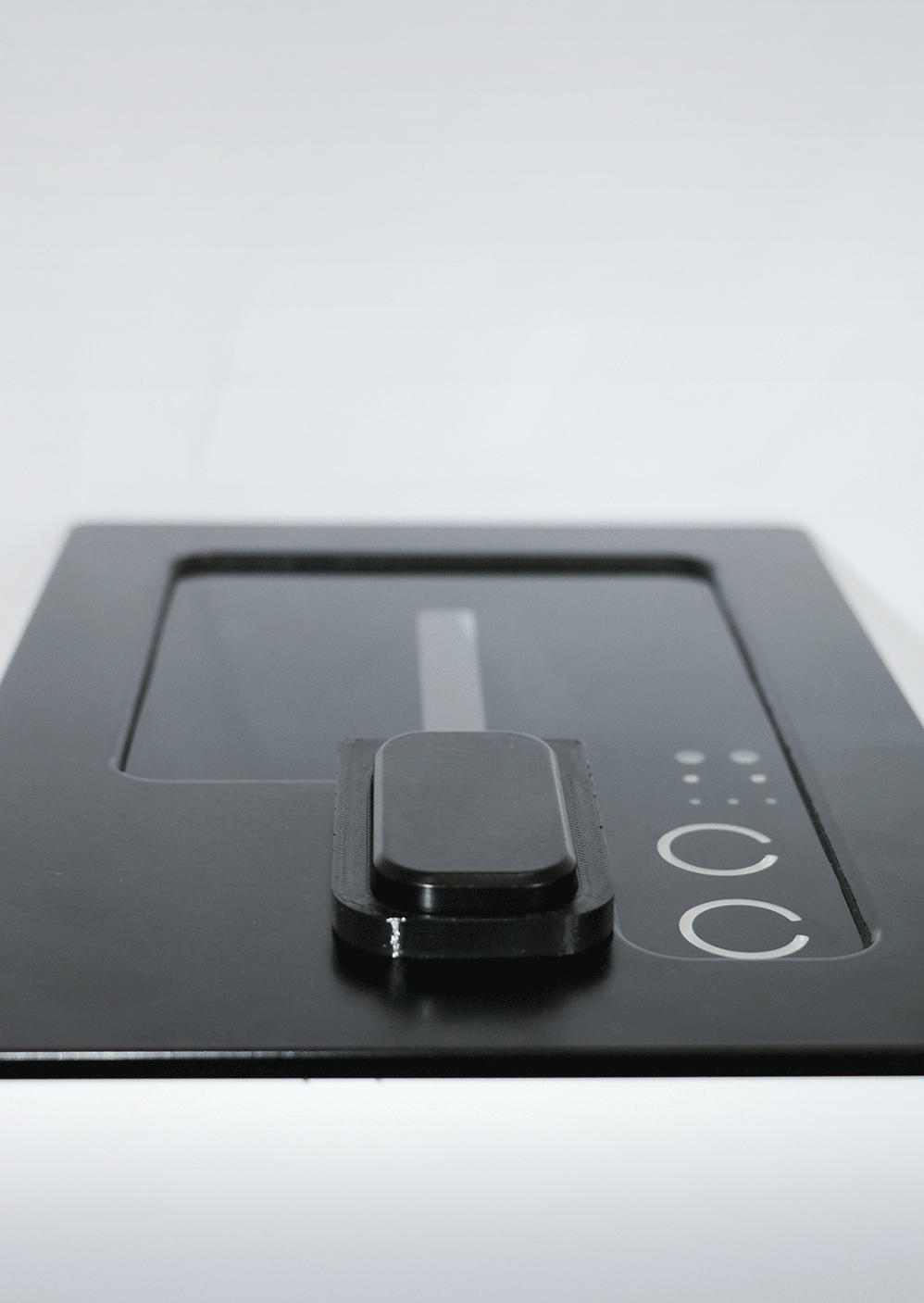

Finder X: NIR-Spectroscopy

The Finder X is a reliable and powerful NIR analysis system for fast and reproducible measurement results in the laboratory and production. Whether for process monitoring or the analysis of intermediate and end products – the system delivers precise results for samples of all kinds.

Advantage overview

- Cost reduction and profit maximisation

- Minimised effort for sample preparation

- Reduction of analysis times and laboratory costs

- Supplier control and optimisation of raw material usage

- Precise achievement of target parameters

- Monitoring, optimisation and standardisation of the production process

- Checking the quality of the end product

- Shortening the release time for end products

In the pharmaceutical industry, the Finder X impresses with its efficiency, flexibility and easy integration into existing quality processes. The system is also successfully used in other industries, such as food and meat processing.

A robust device design with IP31 protection and comparable construction, as well as a thermally stabilized detector, ensure reliable operation – even under changing environmental conditions. Optical reference standards in the device enable automatic control of measurement stability and contribute to the long-term accuracy of results.

The user-friendly software can be flexibly configured: input parameters, report formats and user rights can be individually adapted to your processes – ideal for validated environments with high demands on documentation and traceability.

The analysis is carried out using near-infrared light and is particularly suitable for quick process control. Within a few seconds, essential ingredients such as water, fat, saturated fatty acids, protein, salt and ash can be reliably determined. This makes the Finder X ideal for the quick quantification of active and excipient ingredients, carrier materials and for batch control.

Basic calibrations are already available for numerous applications. In addition, we are happy to develop customized calibrations for your specific products. Alternatively, powerful calibration software enables you to create quantitative or qualitative models independently. Thanks to the standardized interface, new applications can be easily integrated.

Note: Hiperscan is already certified by an NRTL as a manufacturer for the North American market.

The certification of our devices for the North American market is currently in progress.